- 0321-4777776

- nazirchemical@gmail.com

- 7 Race Course Road, Lahore

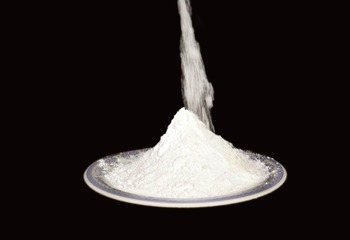

Precipitated Calcium Carbonate

Precipitated Calcium Carbonate

Precipitated calcium carbonate (PCC) is an innovative product derived from lime, which has many industrial applications. PCC is made by hydrating high-calcium quicklime and then reacting the resulting slurry, or “milk-of-lime”, with carbon dioxide. The resulting product is extremely white and typically has a uniform narrow particle size distribution. PCC is available in numerous crystal morphologies and sizes, which can be tailored to optimize performance in a specific application.

We are producing different grades of Precipitated calcium carbonate like Regular product D90 10-12 micron, ultra fine D90 5-8 micron ,Coated presipitated Calcium carbonate along with different micron sizes. We are also using latest tecnoligy used for drying "spin flash dryer" for the atmost dry product.we have Complete range of test exipments for maintaning quality.

Precipitated Calcium Carbonate is wildly used as filler its chemical formula is CaCo3.

Common application of Calcium is in paints, papers, plastic products & filler masterbatches. In paints it is used as an alternative of TiO2. It is used to optimized the cost and to increase mechanical properties, gloss and opacity. It is used in paper Industries to optimize the cost and for the brightness of pages Calcium carbonate increases puncture resistance of films. It reduces cycle time and improves impacts strength due to even distribution of heat into the product. Improves the dimensional stability of building products. It also reduces shrinkage & improves heat dissipation.

Use of PCC in the Paper Industry

With the alkaline conversion of the uncoated freesheet market and the continuing trend toward alkaline vs. acid process papermaking in the coated, ground wood and paperboard markets, PCC is well established as a filler and coating pigment for premium quality paper products. PCC is typically produced in slurry form at satellite plants located near paper mills. PCC enhances optical properties and print characteristics of paper products, improves paper machine productivity, and can reduce papermaking costs through the replacement of more expensive pulp fiber and optical brightening agents. Constantly improving quality targets make the brightness of paper, and thus PCC, an increasingly important factor.

Use of PCC in Polymer Applications

PCC also finds many industrial uses due to its ability to achieve small particle sizes and special crystal shapes. In rigid polyvinyl chloride (PVC), such as vinyl siding and fencing, PCC increases impact strength with some of the smaller particles able to replace expensive impact modifiers. Nano PCCs (less than 0.1 micron in size) control viscosity and sag in automotive and construction sealants, such as PVC plastisols, polysulfides, urethanes, and silicones. In paint, PCC's unique particle shapes improve hiding and allow reductions in titanium dioxide levels.

Use of PCC in Healthcare Applications

An effective acid neutralizer, PCC is often used in calcium-based antacid tablets and liquids. Being high in calcium content, PCC enables the formulation of high dosage calcium supplements and multi-vitamin/mineral tablets. The small particle sizes and special particle shapes contribute to the development of good tasting calcium fortified foods and beverages.